Mechanical Engineering

- Home

- Mechanical Engineering

Department of Mechanical Engineering

Bachelor of Engineering in Mechanical (NBA Accredited) Stream is affiliated to Rajiv Gandhi Technical University (RGTU), Bhopal, Approved by All India Council for Technical Education (AICTE), and the statutory body of the Govt. of India. The Department of Mechanical Engineering is continuously striving to achieve excellence in education, academic and industry oriented research as well as consultancy work with service to the society.

We aim to provide our students with a perfect blend of intellectual and practical experiences that helps them to serve our society and address a variety of needs. At the end of our program, students are prepared for entry-level work as a mechanical engineer as well as for the post-graduate study in mechanical engineering or in another discipline, where a fundamental engineering background constitutes a desirable foundation.

Academic course work and projects are designed to endow students with the ability to apply knowledge of science, mathematics, and engineering, and the capability to work effectively in multidisciplinary teams, providing leadership and technical expertise. With a solid grounding in the principles and practice of mechanical engineering, our undergraduates are ready to engage in ethical approaches to engineering, with concern for society and the environment.

Courses Offered:

Details:B-Tech 4 yr.

USPs: The Department has experienced faculty members who are experts in different domains. In order to keep pace with updated technology in Mechanical engineering, technical events, workshops, industrial visits, hands on training, expert talks and seminars are organized from time to time. The department works closely with the nearby industries on various consultancy projects.

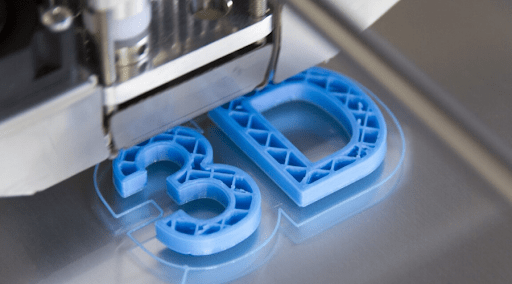

Other than the labs prescribed by the university, the department has SKF-Centre of Excellence, Mechatronics Lab, Electric Vehicle Lab, Advanced Robotics Lab, SAE-BAJA Design Lab, Industrial CNC Turning Centre, and 3-D Printing Lab.

Seats Available: B-Tech 4 yr. – Intake 60

BTech

| Course | Intake |

| Mechanical Engineering | 60 |

Vision of the Institute

To be an academic leader for the development of human potential so as to meet the global challenges.

Mission of Institute

- To create an intellectually stimulating learning environment.

- To impart value based, innovative, and research oriented education.

- To develop positive attitude with communication skills.

- To increase employability and entrepreneurship through collaboration with industries and professional organizations.

Vision of Department

To be a place where the quality education, research and outreach programs synergize for the benefit of society through Mechanical Engineering.

Mission of Department

- To facilitate quality education to undergraduate students.

- To encourage outreach research and competitive academic programs along with cognitive learning to become Center of Excellence.

- To provide cultural synergy and a value driven environment to develop well groomed technocrats, professionals and entrepreneurs.

PSOs of Department

- Analyze, design, evaluate and maintenance of mechanical components as per the given specifications and monitoring using engineering and design analysis software tools.

- Analyze, design, operate and maintain thermal systems including IC engines, heat exchangers, refrigeration & air-conditioning, and power generating systems.

- Develop process plans and apply modern methods to manufacture components and innovative methods and systems with quality assurance.

Program Educational Objectives (PEOs)

The program educational objective of Mechanical Engineering Department is to produce graduate mechanical engineers who:

| PEO 1 | The students will have strong foundation in mathematics, science and engineering fundamentals necessary to formulate, and analyze engineering problems and have strong interpersonal and analytical ability for solving engineering & applications in design, manufacturing, materials, automobile and thermal engineering / fluid systems in the industry. |

| PEO 2 | The student will foster innovation, invention and entrepreneurship by transforming the student’s ideas to proof-of-concepts for high-tech applications and novel solutions for real life problems. |

| PEO 3 | The students will have ability for pursuing higher education, research and development in science and technology. |

| PEO 4 | The students will inculcate a culture & attitude of the continuous learning and to develop ethical code and practices in professional career and society. |

News letters of Mechanical Engineering Department

ME Laboratories & Facilities

The Mechanical Engineering Department is richest in terms of lab facilities available for hands on experience and practices to the Student. The department is having 18 well equipped Labs/ Workshop. They are:

Laboratories

- Basic Mechanical Engineering

- Engineering Graphics

- Workshop Practice

- Manufacturing Process

- Strength of Materials

- Theory of Machine & Mechanics

- Fluid Mechanics

- Machine Drawing & CAD

- Energy Conversion

- Mechanical Measurement & Control

- Dynamics of Machine

- Design of Machine Element

- Thermal Engineering and Gas Dynamics

- Metal Cutting and CNC Machines

- Heat & Mass transfer

- Computer Aided Engineering

- Mechanical Vibration & Noise Engineering

- Operation Research & Supply Chain

- Automobile engineering

- Machine Design

- Refrigeration & Air Conditioning

- CAD/CAM/CIM

- CFD/FEM/Scilab

- Minor Project & Seminar

- Industrial Training

- Computer Programming-I

- Computer Programming-II

- Material Technology

- Machine Tool Technology

- Modern Practices in Manufacturing and Management

- Power Plant Engineering

- 3D Printing Lab

- Mechatronics Lab

Facilities:

- We have well equipped class rooms with projectors & laptop.

- We have experienced faculties who are specialized in different fields.

- Stress free learning audio-video classrooms, seminar halls, board rooms, discussion rooms with modern furniture, LCD and OHP, exclusive facilities for tutorial, workshops make studying at AITR a pleasure.

- Well equipped project laboratories of Thermal Engineering, Fluid Mechanics, I.C. Engines, HMT, Machine Drawing & Design, Theory of Machines, Work shop.

- Wi-Fi zone and Leased Line Internet.

- Departmental Library with more than 2000 books and no. of National and International Journals and subscription of magazines.

- On line lectures of National and International Experts through EDUSAT.

- Regular Industrial visits for practical exposure.

- Technical and Soft Skill Training for campus selection like Auto CAD, Basics and advance Design in CREO and analysis using HYPERWORKS.

- We are also providing consultancy to different industries.

- We organize guest lecturers of experts from Industries.

“Knowledge is of no value unless you put it into practice.” Technology is evolving and so are we as the Department of Mechanical Engineering. In this era of fast and disruptive changes, one must strive to be at the fore-front of the technological developments.

The Department offers best hands-on experience on industry projects, internship opportunities in core industries, collaborative research opportunities and skilling programs on latest technologies which help them in their holistic personal and professional growth. Many interdisciplinary laboratories have been developed to achieve the goal of providing one of the best Mechanical Engineers to the society.

Experienced faculty members along with enthusiastic students form a great team which helps the students to be more confident and progressive in choosing their career of interest. Students are actively involved in the domain of Electric Vehicles, Robotics, Rapid Prototyping, Artificial Intelligence, etc.

The department works with the objective of addressing critical challenges faced by the industry, society and the academia. Perhaps even more important is our unceasing commitment to our students, helping them to learn, grow, develop, and achieve their goals in their pursuit to excel in their professional career. We strive to impart the best of the theoretical and practical knowledge to our students and will continue to do so.

We welcome the students to the Department of Mechanical Engineering as undergraduate student and we hope to be part of your success.

Dr. Amit Kumar Marwah

Professor and Head

Department of Mechanical Engineering

Email:hodme@acropolis.in

| Faculty Name | Designation |

| DR. AMIT KUMAR MARWAH | Professor |

| DR PRASHANT GEETE | Professor |

| MR. HEMANT MARMAT | Associate Professor |

| MR. ABHISHEK SHARMA | Associate Professor |

| MR. SAURABH JAIN | Associate Professor |

| MR. HIMANSHU BHIWAPURKAR | Associate Professor |

| DR. ABHINAV GIRI | Sr. Assistant Professor |

| MR. VEERANDRA PATIL | Assistant Professor |

| MR. NEERAJ GAUTAM | Assistant Professor |

| MR. PRAKASH GAWALI | Assistant Professor |

| MR. UMESH CARPENTER | Assistant Professor |

| MR. VIJAY CHOUDHARY | Assistant Professor |

| MR. AMIT CHANDSARKAR | Assistant Professor |

| MR. HIRAMAN N. SIKDAR | Assistant Professor |

| MR. AMIT KUMAR KUNDU | Assistant Professor |

| MR. RAKESH PUNDAD | Assistant Professor |

| MR. CHANDRA SHEKHAR KORIA | Assistant Professor |

| MR. ANKIT GUPTA | Assistant Professor |

| MS. FALGUNI GORANA | Assistant Professor |

| MR. VINEET PARATE | Assistant Professor |

| MR. VED PRAKASH VISHWAKARMA | Assistant Professor |

| MR. GURDEEP SINGH SALUJA | Assistant Professor |

Laboratories

- Basic Mechanical Engineering: The labs typically include experiments related to mechanics, materials science, thermodynamics, fluid mechanics, control systems, and robotics. The laboratory sessions provide students with an opportunity to develop technical and problem-solving skills, design experiments, analyze data, and communicate their findings effectively.

- Engineering Graphics: Engineering Graphics lab provides hands-on experience to students on various graphical and technical skills. It focuses on developing skills in drafting, modeling, and designing using computer-aided design (CAD) software, as well as manual drawing tools. The lab typically includes exercises related to orthographic projection, isometric projection, sectioning, dimensioning, and sketching.

- Strength of Materials: The Strength of Materials lab provides a hands-on experience in carrying out tests such as tensile tests, compression tests, bending tests, torsion tests, and impact tests. These experiments enable students to measure and analyze the material’s response to various forces and deformations, and determine its mechanical properties. In summary, the Strength of Materials lab provides engineering students with practical skills in material testing, reinforced learning of theoretical concepts, and helps them to develop a deeper understanding of the behavior of materials under stress and strain.

- Theory of Machine: Theory of Machines lab focuses on studying the kinematics and dynamics of different types of machines, including simple mechanisms, gears, cams, and followers. The main objective of this lab is to provide students with practical experience in analyzing and designing different mechanical components and systems. The lab enables students to conduct experiments using various equipment like universal testing machines, torque meters, dynamometers, and other measuring instruments.

- Fluid Mechanics: Fluid Mechanics Lab is an essential component of the mechanical engineering curriculum, focusing on the study of fluids’ behavior under various conditions. Students experiment with a wide range of equipment like manometers, pitot tubes, venturimeters, orifice these are the hottest jordan 3s dropping this summer meters, and hydraulic turbines. Through these experiments, they learn fundamental concepts in fluid mechanics such as viscosity, surface tension, Bernoulli’s principle, and hydraulic jump.

- Mechanical Measurement & Control: The Mechanical Measurement & Control Lab allows students to experiment with various instruments like load cells, pressure gauges, displacement sensors, thermocouples, LVDTs, RTDs, and strain gauges. Through these experiments, they learn fundamental concepts in measurement such as accuracy, precision, linearity, hysteresis, and repeatability.

- Dynamics of Machine: The Dynamics of Machine Lab allow students to experiment with different machines like flywheels, governors, balancing machines, camshaft apparatus, and vibration analysis equipment. Through these experiments, they learn fundamental concepts of vibration, machinery dynamics, and the analysis of mechanical systems.

- Thermal Engineering and Gas Dynamics: The Thermal Engineering and Gas Dynamics Lab allow students to experiment with different equipment used in thermodynamics and heat transfer like heat exchangers, refrigeration cycles, IC engines, boilers, etc. Through these experiments, they learn fundamental concepts of energy conversion, thermal efficiency, heat transfer coefficients, and the analysis of thermal systems.

- Heat & Mass transfer: The Heat & Mass Transfer Lab allow students to carry out experiments using different types of equipment like heat exchangers, shell, and tube heat exchangers, forced convection apparatus, and radiative heat transfer apparatus. Through these experiments, they learn about the various physical phenomena associated with heat transfer and become familiar with techniques used to control it.

- Mechanical Vibration & Noise Engineering: The Mechanical Vibration and Noise Engineering Lab allow students to carry out experiments on different types of equipment like vibration exciter, balancing machine, modal analysis apparatus, and sound level meter. Through these experiments, they learn about various physical phenomena associated with mechanical vibrations and noise, such as natural frequency, damping ratio, resonance, transfer function, and sound power levels.

- Automobile engineering: Automobile Engineering Lab allow students to gain practical exposure by working on different types of equipment like Engine Test Rig, Chassis Dynamometer, and Emission Control Equipment, etc. These experiments help them learn about various physical phenomena associated with automotive systems such as thermodynamics, heat transfer, fluid mechanics, and combustion.

- Refrigeration & Air Conditioning: The Refrigeration & Air Conditioning (RAC) Lab allow students to learn about different types of refrigerants, their properties, and applications. They also learn about different refrigeration cycles such as Vapor Compression Cycle, Vapor Absorption Cycle, and other cooling methods like Air cycle refrigeration and Thermo-electric refrigeration.

- CAD/CAM/CAE: The CAD/CAM/CAE lab is a state-of-the-art facility designed to provide students with practical exposure and hands-on experience in using Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE) tools. The lab has leading software packages for CAD, CAM, and CAE that include SolidWorks, AutoCAD, ANSYS, and other simulation software.

- Material Technology: The Material Technology lab allow students to learn about the fundamental principles of materials science, including the structure, composition, and properties of different types of materials such as metals, ceramics, polymers, and composites. They gain practical knowledge of various testing standards, such as mechanical tests like tensile, compression, torsion, bend, and impact testing, fatigue, creep, hardness, and tribology. Likewise, they also learn about non-destructive testing methods using ultrasonic, x-ray diffraction, and optical microscopy.The mechanical engineering campus infrastructure provides students with state-of-the-art facilities, advanced equipment, and modern technology that are essential for their academic progress and professional development. Other than these, we have

SKF Center of Excellence:

The Department of Mechanical Engineering partnered with SKF India Ltd. to start SKF-Center of Excellence in which training will be provided for courses under various modules which are highly recognised by the industries. In SKF-COE hands-on-training is provided on subjects such as bearing maintenance technology, mounting and dismounting, root cause analysis of bearing damage, condition monitoring, vibration analysis, dynamic balancing etc. These modules are available for the first time in Central India in the Acropolis’ SKF-COE. This will not only benefit the students, but also the different level officials of the industries. Students will get a new exposure especially by linking their technical knowledge with practical knowledge in the COE.

Mechatronics and Automation Lab:

Mechatronics Lab is a hands-on-training Lab to synchronize students of Mechanical Engineering with current industrial developments especially in Automation. Mechatronics Lab has been started January 2022 in the department to train students in understanding amalgamation of electronics, CS, IT, Artificial Intelligence, Machine learning in any engineering system and to create new era in the field of Robotics and Industrial Automation.

Artificial intelligence and Robotics Lab:

Department of Mechanical Engineering and Department of Electronics and Communication Engineering together initialized an Advance Robotics Lab which focuses on the Area of Flexible Manufacturing and Advance Robotics. Following experiments are available here:

- Flexible manufacturing system is the advance manufacturing systems which don’t require the human interference to complete the process. It is type of the didactic system which demonstrates the working of the automated Manufacturing system. System includes the use of the pneumatic actuator, suction cup, vacuum ejector & different solenoid valve.

- THE RV-FR 6-axis Mitsubishi robots backed by the industry’s best initial warranty feature “Next-Generation” capability with payloads from 2 – 20KG. Designed to provide maximum productivity with minimal effort, the MELFA RV-FR-Series line of robots are ready to tackle all of your automation needs. With the MELFA Safe Plus feature “safe, collaborative work applications” allow robots and people to work together with high levels of safety while still providing the speed and performance the industry demands.

Automotive Racing and Design centre:

Department of Mechanical Engineering works with the automotive societies like SAE BAJA, GO-Kart and SUPRA where the team of students works on the mechanical and electric vehicles. This Design Centre offers a multi-disciplinary approach in understanding the automotive industry.

Electric Vehicle Research and Training Center:

Department of Mechanical Engineering and Department of Electronics and communication Engineering bring together experts from various industries to investigate and help address the barriers to the widespread introduction of electric vehicles as “Electric Vehicle Research & Training Centre”. This Research Centre e offers a multi-disciplinary collective approach in understanding the impact of electrification on the future of mobility and the future of the industry. This complex challenge is handled by conducting fundamental research, working with industry and other stakeholders.

3D Printing and Rapid prototyping Lab:

3D printing lab is equipped with a variety of printers that can produce objects in different sizes, shapes, and materials such as plastic, metal, and ceramic. Users can bring their own designs or choose from a library of existing templates to print out their desired items. The benefits of 3D printing lab include the ability to prototype and test designs quickly and inexpensively, produce customized or one-of-a-kind objects, and reduce waste and environmental impact by printing only what is needed.

Centralized workshop:

Mechanical Workshop facility provides students with practical hands-on experience related to the design, fabrication, and repair of mechanical systems and equipment. The main purpose of a mechanical workshop is to provide students with the opportunity to apply theoretical concepts learned in the classroom to real-world scenarios. The workshop is equipped with a variety of tools and machinery that help students build, modify, and test different mechanical components and systems. The primary focus of the workshop is to develop the technical skills of students in areas such as metalworking, welding, machining and Assembling.

S.no | Enrolment Number | Student Name | Company Placed in |

| 1 | 0827ME191020 | Harsh Pradeep Garud | Capgemini |

| 2 | 0827ME191021 | Harsh Sahu | Capgemini |

| 3 | 0827ME203D14 | Shubham Magarde | Capgemini |

| 4 | 0827ME191058 | Shubham Verma | Capgemini |

| 5 | 0827ME191069 | Yash Jadhav | Capgemini |

| 6 | 0827ME191007 | Akshat Rathore | ConsultAdd |

| 7 | 0827ME191041 | Prakhar Upadhyaya | ConsultAdd |

| 8 | 0827ME191059 | Sourabh Pandey | JASH Engineering |

| 9 | 0827ME191002 | Abhishek Choudhary | LiuGong |

| 10 | 0827ME191015 | Devashish Tripathi | LiuGong |

| 11 | 0827ME203D08 | Jap Sharma | LiuGong |

| 12 | 0827ME191038 | Neeraj Bhayal | LiuGong |

| 13 | 0827ME191055 | Shivanshu Yadav | LiuGong |

| 14 | 0827ME203D01 | Aman Patil | TCS Ninja |

| 15 | 0827ME191019 | Garima Choubey | Varroc, General Motors |

| 16 | 0827ME191005 | Aditya Bhatnagar | Volvo Eicher, Michelin Tyres |

| 17 | 0827ME191028 | Khushhal Mittal | Volvo Eicher |

| 18 | 0827ME191064 | Vedant Shriram Paranjape | Volvo Eicher |

| 19 | 0827ME191032 | Madhuram Dubey | Sanoh India Pvt. Ltd. |

| 20 | 0827ME191008 | Amit Verma | Hindustan Unilever Ltd. |

| 21 | 0827ME191006 | Akhil Sharma | Hindustan Unilever Ltd. |

| 22 | 0827EC191018 | Chirag Awasthi | Hindustan Unilever Ltd. |

| 23 | 0827ME191024 | Harshit Choudhary | LiuGong |

| 24 | 0827ME191014 | Devansh Verma | LiuGong |

| 25 | 0827ME191029 | Kuldeep Singh Rana | Mackvalves |

| S.no | Faculty Name | Innovation Description | Session |

| 1 | Dr. Amit Kumar Marwah | An Electric Vehicle Flexible Charging System using IoT | 2023 |

| 2 | Dr. Amit Kumar Marwah | Blueprint of Green Sustainable and Clean Renewable Energy | 2023 |

| 3 | Dr. Abhinav Giri | Experimental Investigation of Concentric Tube Heat Exchanger | 2023 |

| 4 | Mr. Abhishek Sharma | IoT based device for home security | 2023 |

| 5 | Sachin Mittal | THREE STAGE INDIRECT-DIRECT EVAPORATIVE AIR COOLER | 9/27/2019 |

| 6 | Sachin Mittal | ECO FRIENDLY HYBRID COOLER WITH VENTILATION UNIT | 04-09-2020 |

| 7 | Amit Kumar Marwah | A METHOD FOR WASTE WATER PURIFICATION AND SYSTEM THEREOF | 6/22/2018 |

| 8 | Abhishek Sharma | SYSTEMATIC APPROACH FOR MONITORING THE POLLUTION CONTROL IN SMART CITIES AND ADDRESSING THE SECURITY CHALLENGES INTEGRATED WITH IOT | 10-07-2022 |

| 9 | Abhishek Sharma | Artificial intelligence and machine learning based autonomous e -waste management system for smart environment | 3/18/2022 |

| 10 | Dr. Prashant Geete | Intelligent Garbage Collection and Alarm System Based on IoT | 10-01-2021 |

| 11 | Dr. Prashant Geete | The Internet of Things (IoT) based cost-effective and simple solutions for energy robbery finding and error analysis | 10-01-2021 |

| 12 | Dr. Prashant Geete | Internet of Things (IoT)-based Information collection system for efficient production in large scale industries. | 10/29/2021 |

| 13 | Dr. Prashant Geete | Internet of Things Based Wearable intelligent device for Next Generation- Healthcare Sector | 01-07-2022 |

| 14 | Dr. Abhinav Giri | A SOLAR DRYER FOR AGRICULTURAL PRODUCT | 04-09-2021 |

Title of the Magazine: | The Differential |

| Publishing Date: | June – 2020 (Volume 5, Issue 1) |

| Sept – 2021 (Volume 6, Issue 1) | |

| Dec – 2022 (Volume 7, Issue 1) | |

| Magazine Link: | |

https://drive.google.com/file/d/1dYyiNl2EhWrcZsPlzFv2IageWonZK-Em/view?usp=share_link |

| S.No. | Department | Name Of Faculty | Type Of Achievement | Year | Description |

| 1 | ME | Dr. Amit Kumar Marwah | Paper Published | 2023 | Sustainable Business Practices in Indian Manufacturing Industries: Some Case Studies |

| 2 | ME | Dr. Abhinav Giri | Paper Published | 2023 | Analysis of double pipe heat exchanger |

| 3 | ME | Dr. Abhinav Giri | Paper Published | 2023 | Performance Evaluation of a Home Refrigerator by Modifying Condenser Fin Design |

| 4 | ME | Dr. Abhinav Giri | Paper Published | 2023 | Review of the improvement of heat transfer in heat exchanger using porous medium |

| 5 | ME | Dr. Abhinav Giri | Paper Published | 2023 | Vortex Tube Localized Colling Powered by Solar PV |

| 6 | ME | Mr. Neeraj Gautam | Paper Published | 2023 | Comparative analysis of Battery Technologies for Electric Vehicles |

| 7 | ME | Mr. Amit Kumar Kundu | Paper Published | 2023 | Innovative Top 5 Iconic Baseball Cards from the 1940s Inventory Management Strategies for Small Businesses |

| 8 | ME | Mr. Amit Kumar Kundu | Paper Published | 2023 | The Role of Cultural Intelligence in Cross-Border Mergers and Acquisitions |

| 9 | ME | Mr. Amit Kumar Kundu | Paper Published | 2023 | Improving Production and Inventory Forecasting with Big Data Analytics |

| 10 | ME | Mr. Amit Kumar Kundu | Paper Published | 2023 | Basics of Manufacturing Processes of Composite Materials |

| 11 | ME | Mr. Rakesh Pundad | Paper Published | 2023 | Performance Evolution of a Home Refrigeror by Modifying Condenser Fin Design |

| 12 | ME | Mr. Prakash Gawli | Paper Published | 2023 | Basics of Manufacturing Processes of Composite Materials |

| 13 | ME | Mr. Prakash Gawli | Paper Published | 2023 | Improving production and Inventory Forecasting with Big Data Analysis |

| 14 | ME | Prof C.S. Koria | Paper Published | 2023 | Reinforcement of micro and nano material with aluminum alloy (Al7075)metal matrix composite |

| 15 | ME | Dr. Abhinav Giri | Research Paper | 2022-23 | Design a smart structure to dampen a vibrations of Euler-Bernoulli beams” |

| 16 | ME | Prof. Abhishek Sharma | Research Paper | 2022-23 | A Review Paper of Composite Materials: Advantages and Applications |

| 17 | ME | Prof. Abhishek Sharma | Research Paper | 2022-23 | Energy Generation by using Small Hydro Power – An Analysis |

| 18 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | Optimization of a Vehicle Assembly Line |

| 19 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | Shaft Driven Lapifit |

| 20 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | Hydropower an Efficient Source of Energy: An Analysis |

| 21 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | Energy Generation By Using Small Hydro Power- An Analysis |

| 22 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | A review paper of Composite Materials: Advantages and Applications |

| 23 | ME | Prof. Amit Kundu | Research Paper | 2022-23 | Variation in mechanical properties of wire due to variation of speed in wire drawing process |

| 24 | ME | Prof. Ankit Gupta | Research Paper | 2022-23 | Experimental investigation of force transmissibility for ferrous and non-ferrous materials |

| 25 | ME | Prof. Ankit Gupta | Research Paper | 2022-23 | Experimental Investigation of Force Transmissibility for Natural Fiber Composite Materials |

| 26 | ME | Prof. Prakash Gawali | Research Paper | 2022-23 | Variation in mechanical properties of wire due to variation of speed in wire drawing process |

| 27 | ME | Prof. Amit Kundu | NPTEL Certification | 2022-23 | Welding of Advanced High Strength Steels for Automotive Applications |

| 28 | ME | Prof. Amit Kundu | NPTEL Certification | 2022-23 | Introduction to Machine Learning |

| 29 | ME | Prof. Amit Kundu | NPTEL Certification | 2022-23 | Manufacturing Guidelines for Product Design |

| 30 | ME | Prof. Amit Kundu | NPTEL Certification | 2022-23 | Traditional and Non-Traditional Optimization Tools |

| 31 | ME | Prof. Hemant Marmath | E-BAJA 2022 | 2022 | Winner of Dronacharya Award |

S.no | Enrolment Number | Student Name | Description | Month and Year |

| 1 | 0827ME191047 0827ME191013 | Purnesh Agrawal and Deepika purohit | research paper in IJAEM on “ A review paper of Composite Materials: Advantages and Applications”. | Nov-22 |

| 2 | 0827ME201015 | Samarth Sharma | represented RGPV University at national level in (Mallakhamb) sport | 2022 |

| 3 | 0827ME191032 | Neeraj Bhayal | completed C++ Nano degree course by PrepInsta Technologies | 2022 |

| 4 | 0827ME191033 | Neeraj Bhayal | completed a course on AI for Everyone by IBM and Offered through Edx | 2022 |

| 5 | 0827ME191034 | Neeraj Bhayal | completed a course on Ethics in AI and Big Data by Linux Foundation and Offered through Edx | 2022 |

| 6 | 0827ME191035 | Neeraj Bhayal | completed a course on Excel Skills for Business by Macquarie University and offered through Coursera | 2022 |

| 7 | 0827ME191036 | Neeraj Bhayal | completed a course on MATLAB On-ramp Training and certificate by Mathworks | 2022 |

| 8 | 0827ME191037 | Neeraj Bhayal | completed a course on Advanced Manufacturing Process Analysis authorized by University at Buffalo and The State University of New York and offered through Coursera | 2022 |

| 9 | 0827ME191038 | Neeraj Bhayal | completed a course on Basics of Financial Markets by Elearnmarkets | 2022 |

| 10 | 0827ME191044 | Purnesh Agrawal | earned a Certificate of the leadership in the club named Acrotronics | 2022 |

| 11 | 0827ME191045 | Purnesh Agrawal | earned a Certificate of the fevicryl workshop of Dabu art, meenakari, Empasto knife painting. | 2022 |

| 12 | 0827ME191046 | Purnesh Agrawal | earned a Certificate of the fevicryl workshop of Sun painting, reverse decoupage, junbari pandent. | 2022 |

| 13 | 0827ME191047 | Purnesh Agrawal | earned a Certificate of internship done at Swaraj Technocrafts Pvt. Ltd. | 2022 |

| 14 | 0827ME213D07 | Dheeraj Pawar | completed NPTEL certification course on fundamentals of manufacturing process . | 2022 |

| 15 | 0827ME191059 | Sourabh Pandey | earned a certificate of Six Sigma Yellow belt. | 2022 |

| 16 | 0827ME201004 | Atharv Upadhyay | completed a course on “suspension systems”. | 2022 |

| 17 | 0827ME213D13 | Mayank Ingle | completed Solidworks software course from Indo German Tool Room Indore. | 2022 |

| 18 | 0827ME213D14 | Mayank Ingle | completed course on PHP programming language from Progate. | 2022 |

| 19 | AMIT VERMA | Amit Verma | Completed One Month Internship at INDIAN RAILWAYS | 2022 |